The COVID-19 emergency may be a thing of the past, but if there’s one lasting change that more than a year of lockdowns and social distancing mandates engendered it’s the continued rise of ecommerce. Long gone are the days when shoppers had no choice but to trek through town to peruse the shops when the need to spend hit them. Today, the first touchpoint – and often the last as well – a customer has with a business is typically online.

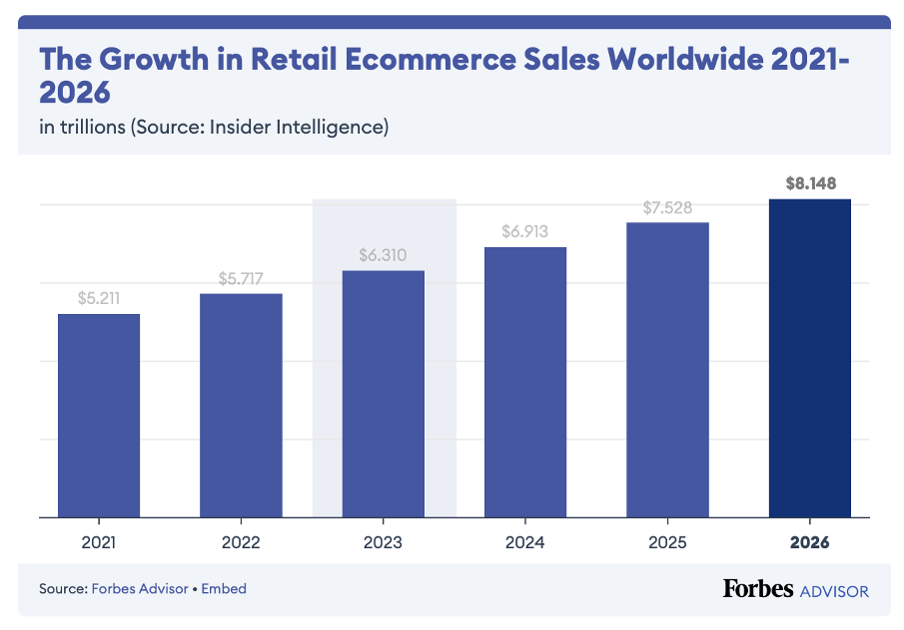

Already on the increase before the world was forced to rethink how business was done back in 2020, ecommerce has grown from strength to strength since the pandemic – and forecasts suggest that this growth will continue. Figures from Forbes reveal that global retail sales will be worth a whopping $6.31 trillion in 2023 and reach $8.148 trillion by 2026.

(Image source: forbes.com)

The picture is clear – any retailer that wants to succeed in the post-pandemic world needs to be competing in the online space. However, in order to do so successfully, the one facet that must be got right is fulfilment.

Why Fulfilment Matters

Today, customers have high expectations when it comes to the delivery times of their online orders. In fact, according to a survey in Statista, when asked how soon they expected to receive their online purchase, 41% of shoppers said they hoped to receive it within 24 hours – while 24% reported wanting it delivered in under 2 hours.

(Imager source: statista.com)

In a separate survey, cited in Forbes, it was found that 22% of customers abandon their online shopping carts because shipping times are too slow.

(Image source: forbes.com)

This means that anyone planning to either improve their ecommerce game or add an online shopping channel to their business for the first time needs to take fulfilment seriously. If it takes days and days or even weeks for you to ship orders, your customers will quickly leave their online shopping session on your site and turn to a competitor with faster shipping times. Indeed, ecommerce and slow shipping are never a good combination. As such, your fulfilment services need to be robust – and this means you will need to utilise the services of a dedicated fulfilment centre.

What Is The Difference Between a Warehouse and a Fulfilment Centre?

In the realm of logistics and supply chain management, the terms "warehouse" and "fulfilment centre" are often used interchangeably, leading to confusion among businesses. While both involve storing physical products, their functions and purposes differ.

Warehouses: Cost-Effective Storage Solutions

A warehouse serves as a dedicated facility offering storage space over extended periods. It's essentially a large industrial space equipped with shelves, bins, pallets and forklifts to efficiently manage inventory. Businesses engaged in wholesale or B2B transactions often utilise warehouses to accommodate inventory in bulk. In addition, some ecommerce businesses either own and operate their own warehouses to manage excess inventory or otherwise opt for rental options based on their storage needs. Warehouses will also typically need scheduled, less frequent pickups, since it is more cost-effective to ship freight and pallets instead of using individual shipping labels.

Renting warehouse space is often a cost-effective and flexible option for small to medium-sized e-commerce sellers, considering the available space and rent terms. However, standard warehouses do not offer the services that fulfilment centres do.

Fulfilment Centres: Orchestrating Order Fulfilment

A fulfilment centre, also known as a distribution centre or 3PL (third-party logistics) provider, is where sellers or outsourced fulfilment companies manage customer orders received through their ecommerce stores (direct-to-consumer) and/or business-to-retail fulfilment for big-box retailers. These centres are typically larger and more sophisticated in terms of fulfilment capabilities than standard warehouses.

The primary function of a fulfilment centre is to provide inventory management, store inventory strategically, ship orders directly to customers and/or retailers and assist sellers in managing the overall fulfilment process, including negotiating low shipping rates with couriers. Some fulfilment centres many also offer expedited delivery options such as same day shipping options, inexpensive ground shipping, or international shipping.

Fulfilment centres have grown in popularity in recent years, offering a complete end-to-end solution for all types of ecommerce business. By outsourcing fulfilment tasks to experienced professionals, ecommerce businesses offload the logistical complexities of storing, picking, packing and fulfilling orders, allowing businesses to concentrate on marketing, selling and enhancing their customer experience.

How Fulfilment Centres Work

In a fulfilment centre, an ecommerce business's inventory is received and temporarily stored in preparation for fulfilling customer orders. Once a shopper completes a purchase on the business's online store, that inventory is picked, packed into a box or poly mailer, and labeled for shipment. Last-mile couriers then collect the labeled packages from the fulfilment centre and deliver them to the end customer.

Fulfilment centres are equipped to handle both business-to-business (B2B) orders, typically involving large quantities of products shipped to major retailers, as well as direct-to-consumer (DTC) orders, which are sent directly to individual consumers' homes.

Overall, the fulfilment process generally looks something like the following:

- Goods are received into the fulfilment centre

- The goods are quality assessed and stored

- Orders are received and processed via the seller’s ecommerce store

- Items for each order are picked and packed according to the seller’s requirements

- Orders are then shipped directly from the fulfilment centre to the customer

- Any returns are also processed by the fulfilment centre

Some centres also offer additional order fulfilment services, such as customer service call centres, delivery tracking and customer notifications.

In essence, fulfilment centres serve as a strategic partner, enabling your ecommerce business to focus on its core strengths while ensuring seamless order fulfilment and enhanced customer satisfaction.

Choosing the Right Fulfilment Centre for Your Ecommerce Needs

There are numerous fulfilment centres offering their services today. Some cater to different corners of the market, so it’s important to do your research before committing to a particular service.

Large 3PLs – like GXO, DHL and Wincanton – offer shared-use fulfilment warehouses for smaller ecommerce companies. These all use state-of-the-art technology to store, pick, pack and fulfil orders on your behalf.

A number of smaller 3PLs who specialise in ecommerce fulfilment have also entered the market. These include James and James, We Are Fulfilment and Fulfilment Crowd. The services offered by these companies can all be seamlessly integrated with your ecommerce sales platform for stress-free shipping and scalable order fulfilment.

In addition, Amazon now offers a service called Fulfilment by Amazon (FBA) – a near end-to-end solution that lets you outsource your ecommerce order fulfilment and shipping services to Amazon.

Find the Perfect Warehouse Fulfilment Centre with FLOX

Whether you're a small startup or an expanding enterprise, understanding the nuances of warehouses and fulfilment centres is crucial for optimising your supply chain operations. By carefully evaluating your business needs order volume, storage and shipping requirements, you can confidently select the most suitable fulfilment company to streamline your operations and enhance the customer experience.

If you’re looking for a platform that makes it easy to find and book the best fulfilment warehouse space in the UK, your search is over. FLOX is a shared transportation and warehousing logistics platform that is dedicated to promoting efficiency, cost savings and sustainability - helping you improve operations across the board. Our platform enables warehouse managers, shippers and logistics service providers to collaborate seamlessly, driving the flow of every order and shipment. With FLOX, there’s no need to sign leases directly with warehouse or fulfilment centre owners or negotiate terms. Instead, our clients sign a standardised set of three-way Terms and Conditions between warehouse provider, FLOX and themselves, which regulates pay-as-you-go use of the warehousing space.

If you don't yet have an account, simply search for Available Storage Capacity or list your Logistics Services with no monthly fees.

Sign up for the FLOX platform and start shaping the future of logistics today.

FAQ

What is the difference between a warehouse associate and a fulfilment partner?

The difference between a warehouse associate and a fulfilment partner primarily revolves around their roles and responsibilities within the supply chain process.

Warehouse Associate

Role: A warehouse associate is typically an employee who works in a warehouse environment. Their primary duties involve receiving, storing, and shipping inventory. They may be responsible for tasks such as picking orders and packing boxes, organising inventory storage, and maintaining the cleanliness and safety of the warehouse.

Focus: Their work is more operational and task-oriented, focusing on the physical handling of goods and ensuring that inventory is properly stored and managed.

Employment Type: Warehouse associates are usually direct employees of a company that owns the warehouse or a staffing agency.

Scope of Work: They are generally involved in the day-to-day warehouse operations within a warehouse and may not engage in broader strategic or customer-facing roles.

Fulfilment Partner

Role: A fulfilment partner, on the other hand, is typically a third-party fulfilment expert that offers comprehensive fulfilment solutions to businesses. This includes not just warehousing but also a range of services such as order processing, packaging, shipping, and managing returns.

Focus: Fulfilment partners focus on the overall efficiency of the order fulfilment process, ensuring that products are stored, picked, packed, and shipped in a manner that meets customer demands and business requirements.

Business Relationship: Businesses collaborate with fulfilment providers to outsource their logistics and fulfilment needs, from the processing to packaging of orders, allowing them to focus on core operations like marketing and product management and development.

Scope of Work: Fulfilment partners manage complex logistics, often integrating technology and systems to streamline fulfilment operations and improve service levels. They may also offer strategic insights on inventory management and distribution.

In summary, a warehouse associate is primarily focused on operational tasks within a warehouse, while a fulfilment partner offers a broader range of services that encompass the entire fulfilment process for businesses. The fulfilment partner serves as a strategic ally, enabling companies to efficiently handle customer orders and improve their overall logistics operations.

How do you optimise the warehouse fulfilment process?

Optimising the warehouse fulfilment process involves several key strategies aimed at enhancing efficiency and reducing operational costs. One of the primary methods is implementing an effective Warehouse Management System (WMS). A robust WMS integrates inventory management, order processing, and shipping logistics into a single platform. This allows businesses to track inventory levels in real time, ensuring that products are available when needed while minimising excess stock. Additionally, automation tools such as barcode scanners and RFID technology can streamline the picking process, allowing workers to quickly identify and retrieve items for shipment, thereby decreasing order processing time.

Another crucial aspect of optimising fulfilment in a warehouse is the strategic layout and organisation of the storage space. By utilising a well-planned floor layout that places frequently picked items closer to packing and shipping areas, businesses can significantly cut down on travel time for workers. Implementing techniques such as slotting, where products are placed based on their sales velocity, further enhances picking efficiency. Moreover, regular analysis of order patterns can help inform decisions about product placement and inventory turnover, ensuring that high-demand items are always easily accessible.

Lastly, fostering a culture of continuous improvement within the warehouse staff can contribute significantly to optimisation efforts. This involves regular training sessions to keep employees updated on new technologies and best practices, as well as encouraging feedback on the fulfilment process. Using performance metrics to evaluate worker productivity and order accuracy can identify areas for improvement while incentivising top performers can motivate staff to adhere to best practices. By focusing on these strategies, businesses can optimise their warehouse fulfilment process, leading to faster order processing, improved customer satisfaction, and ultimately, increased profitability.