There's a reason why flexible pallet storage service facilities can be found in practically every warehouse and distribution centre across the county. Pallet storage isn't just one of the most efficient ways to utilise and maximise storage space – it's also a fantastic way for logistics managers to optimise storage costs, improve supply chain efficiency, and streamline inventory management.

In this blog post, we'll be taking a deep dive into exactly what pallet storage is, why it's the industry standard, and what its benefits are when it comes to enhancing operational efficiency in logistics and warehousing.

What Is Pallet Storage?

Pallet storage is a warehouse organisation method that involves storing goods on sturdy wooden or plastic pallets. Widely employed in logistics, retail, and ecommerce, as well as many other areas and industries, short or long term pallet storage offers a cost-effective and streamlined approach to storing and transporting a diverse range of goods.

Typically, pallets are strategically stacked on racks or shelves within the warehouse, allowing for efficient use of space. Pallets offer a flexible storage option which is designed to accommodate numerous stacking configurations so that location, access and retrieval of goods can all be optimised. As such, palletisation not only enhances inventory management but also facilitates the swift and organised handling of goods, making it a pivotal component in the supply chain landscape.

What Industries Use Pallet Storage?

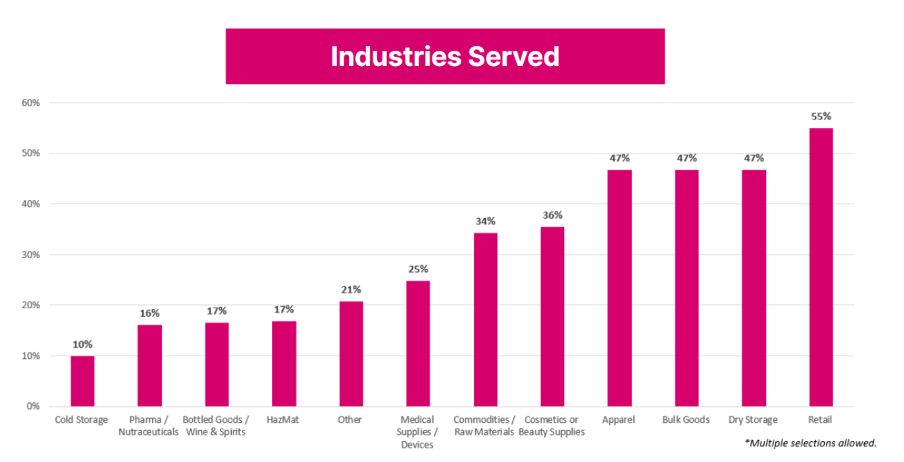

Throughout the country, an enormous range of products – from the tiniest electrical components to bulky single items – are palletised in an extensive network of third-party logistics (3PL) warehouses and sent all over the world every single day. These warehouses provide a crucial pallet storage service to a huge range of industries, from pharma to apparel, bulk goods, medical supplies, and alcohol, to ensure every single supply chain is fit for demand.

(Image source: extensive.com)

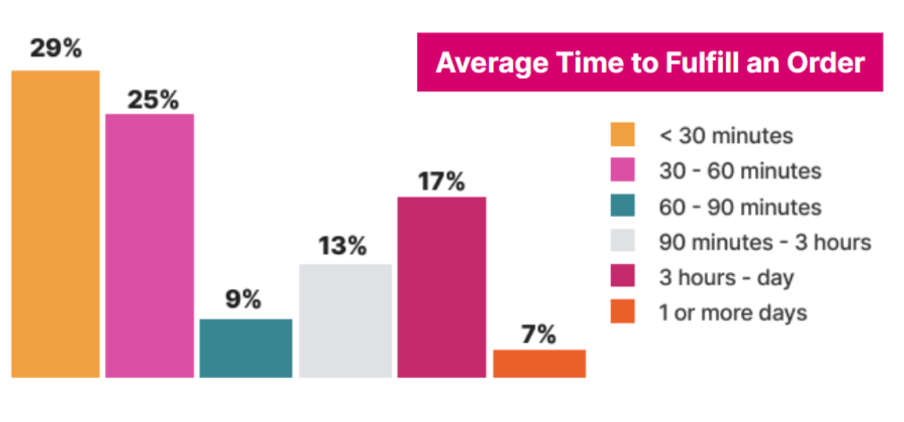

Well-managed storage space and efficient palletisation is indeed essential to warehousing and logistics, and plays a huge part in the fast-improving fulfilment times that the industry is showcasing right now.

(Image source: extensive.com)

Key Benefits of Pallet Storage

Pallet storage stands as the linchpin of the warehouse industry, driven by its fundamental advantages that significantly impact efficiency and profitability. The key benefits of pallet storage include the following.

Rapid Handling

Pallets revolutionise the loading and unloading process, ensuring swift transfers from warehouse racks to lorry backs, saving valuable time in storage and distribution operations.

Consistency

Irrespective of size or shape of goods, pallets provide a consistent and standardised footprint. This means the pallet storage system is brilliantly adaptable and can accommodate anything from delicate ornaments to stacks and stacks of plastic items, and everything in between. With pallets, storage and retrieval are always the same process no matter the product.

Optimised Space Utilisation

Palletisation enables goods to be stored edge-to-edge, maximising storage space in warehouses and lorries, improving efficiency and keeping both storage and transportation costs low.

Swift Unloading

Forklifts were purpose-built for pallets. This synergy facilitates rapid unloading, empowering a single forklift driver to load or unload an entire lorry in a very short space of time.

High Capacity

Pallets can withstand and transport hundreds of kilos of products, expanding storage and transportation capabilities.

Simplified Management

Pallet storage facilitates straightforward tracking of goods and inventory, promoting efficient product organisation.

Elevated Safety Standards

Palletisation significantly reduces the risk of physical accidents by providing a secure and stable environment for stored goods.

Minimised Product Damage

Pallet storage plays a crucial role in reducing the likelihood of product damage during loading and unloading, ensuring goods remain safe and unharmed.

Optimising Warehouse Operations with Effective Pallet Storage

Pallet storage systems are instrumental in enhancing warehouse efficiency across diverse industries. These systems play a pivotal role in advancing inventory management, streamlining picking and packing processes, and maximising storage space.

In the warehouse, pallet racking systems simplify the systematic organisation of inventory. This is because products stored on pallets can be easily labelled and tracked, ensuring a methodical arrangement for efficient retrieval. What's more, a modern pallet storage service will ensure the pallet storage system seamlessly integrates with inventory management software, offering real-time visibility of stock levels. This integration provides logistics managers with precise demand forecasting data, mitigating the risk of supply shortages and surpluses.

Finally, pallet racking systems effectively utilise vertical space within the warehouse, minimising the necessity for expanding footprints, optimising storage capacity, and helping you keep control of overheads. With clearly labelled pallets, efficient storage layouts, and integration with modern systems and software, warehouse workers can locate and retrieve items more easily, keeping warehouse fees low through reduced staffing needs – savings which are passed on to all warehouse clients.

Find the Perfect Warehouse Space with a Flexible Pallet Storage Facility with FLOX

In the dynamic landscape of supply chain operations, whether you're a burgeoning startup or a scaling enterprise, a nuanced understanding of warehouses and pallet storage facilities is indispensable. Successfully optimising your supply chain hinges on a careful assessment of your business requirements, encompassing order volume, storage needs, and shipping demands. In nearly all cases, utilising a pallet storage service will hugely benefit your operations.

If you're searching for a platform that makes it easy to find and book the best warehouse space with pallet storage facilities, your search is over. FLOX is a shared transportation and warehousing logistics platform that is dedicated to promoting efficiency, cost savings and sustainability – helping you improve operations across the board. Our platform enables warehouse managers, shippers and logistics service providers to collaborate seamlessly, driving the flow of every order and shipment. With FLOX, there's no need to sign leases directly with warehouse or fulfilment centre owners or negotiate terms.

Instead, our clients sign a standardised set of three-way Terms and Conditions between warehouse provider, FLOX and themselves, which regulates pay-as-you-go use of the warehousing space.

If you don't yet have an account, simply search for Available Storage Capacity or list your Logistics Services with no monthly fees. Sign up for the FLOX platform and start shaping the future of logistics today.

FAQ

How much does it cost to store a pallet in the UK?

The cost to store a pallet in the UK typically ranges from £1.50 to £5.00 per pallet per week. However, the exact rate can vary based on several factors, including:

Location: Pallet storage prices can be higher in prime locations like London and the M25 compared to the North of England or Scotland.

Quantity of Pallets: Discounts are often available for larger quantities. For example:

- 1 to 300 pallets: £2.00 per pallet per week

- 300 to 1000 pallets: £1.50 per pallet per week

- 1000+ pallets: £1.20 per pallet per week

Pallet Size: Standard rates are generally based on standard pallet sizes (1000mm x 1200mm x 1000mm high).

Additional Services: If you require services like insurance, distribution, or special handling (e.g., cold storage), additional charges may apply.

In addition to the storage fees, there may also be movement fees, typically around £2-£3 per pallet for loading and unloading.

While the base storage costs can range from £1.20 to £5.00 per pallet per week, the total cost can be significantly affected by location, quantity, special handling requirements, and additional services.

How should pallets be stored?

Careful consideration should be given to the method of stacking and the type of racking used to maximise efficiency and safety. One effective approach is utilising single-deep pallet racking, which allows easy access to each pallet while minimising the risk of damage that can occur with block stacking or honeycombing. This method helps ensure that goods can be quickly retrieved and restocked, making it particularly beneficial for high-turnover items. Ensuring adequate aisle space for navigability is also crucial, as it allows forklifts and pallet jacks to manoeuvre effectively, reducing the chances of accidents and enhancing operational efficiency.

Another important factor in pallet storage is the condition and type of pallets being used. It's essential to check that pallets are in good condition, free from cracks or damage, and adequately rated for the weight they will carry. Businesses should consider using stacking frames for non-stackable pallets, which can help organise the storage area and prevent product damage. For businesses dealing with a larger inventory, double-deep pallet racking can be a space-saving solution, allowing for higher storage density with fewer aisles.

Implementing the right combination of storage methods and maintaining the integrity of the pallets ensures a streamlined and effective storage solution that meets operational needs.