Warehouses are not just storage spaces; they are dynamic hubs that drive the efficiency and success of supply chains, adapting swiftly to the evolving demands of modern commerce.

Contents

Warehouses play an integral role in the global economy, acting as vital hubs for storing and transporting goods. In this article, we delve into the world of warehousing and storage services, outlining their importance and diverse offerings.

Understanding the range of storage solutions available is crucial. We explore different warehouse configurations, considering industry-specific needs and capabilities. With the rise of online shopping and increasing customer demands, warehousing services are undergoing rapid transformations.

We explore the expanding role of distribution and fulfilment centres in the supply chain, highlighting the advantages of outsourcing storage services.

Warehousing Services and Solutions

Warehousing services embody far more than just a place to store goods—they offer an intricate suite of solutions that cater to the specific demands of various business sectors. Within the walls of contemporary warehouses, services like kitting, assembly, and cross-docking are seamlessly carried out, providing added value beyond standard storage practices.

3PLs understand the dynamic nature of storage requirements, offering tailored solutions that mould to the contours of any business need, be that for a fleeting project or an enduring partnership. Such flexibility is a boon to businesses seeking versatility in duration, space, and service options.

In an era where supply chain fluidity is paramount, working with third-party logistics providers has become a staple for those looking to outsource warehousing and distribution. This approach frees businesses from the capital and operational constraints of owning and managing warehouse facilities. Instead, they can invest that energy into their core competencies.

Adaptability is a cornerstone of modern warehousing services, accommodating for sudden surges in demand, seasonal peaks, or the pacing growth of a company. Offering scalable solutions, these services ensure that inventory management remains efficient no matter how the storage needs evolve.

Choosing the Right Warehouse Facility

Choosing the right warehousing providers is crucial for streamlining your business's supply chain. Urban warehouses enable quick shipping to dense population centres, leading to faster deliveries and lower costs, enhancing customer satisfaction.

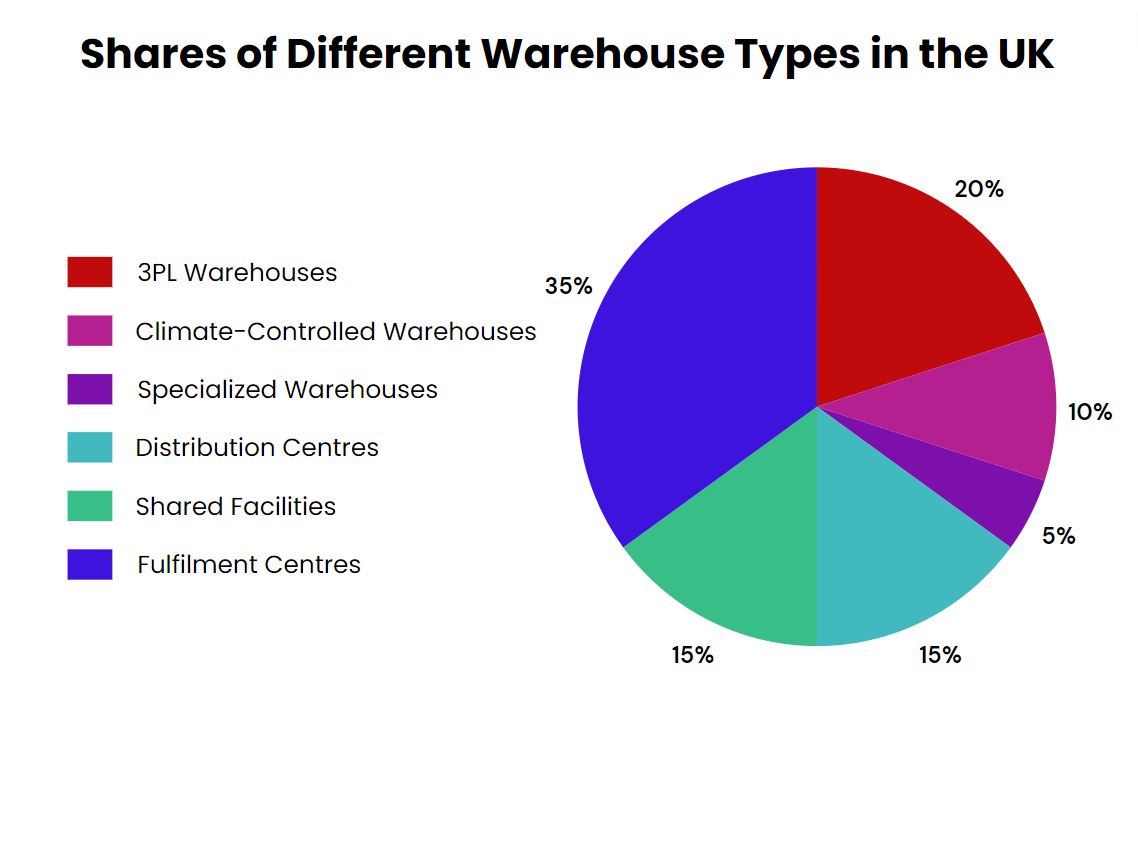

Various warehousing types cater to different industries. Distribution centres facilitate the flow of goods, fulfilment centres manage online orders swiftly, cold storage warehouses handle perishable products, and bonded warehouses store goods under customs regulations.

Deciding between dedicated and shared facilities depends on your specific needs. Dedicated facilities offer maximum security and privacy but are costlier. Shared facilities are more cost-effective, providing flexibility, additional services like inventory management, and transportation, which can improve efficiency.

When thinking about the basics for warehouses, it's important to get t right so we've created a guide to help warehouse owners do just that. It's called Warehouse Best Practice.

Typical Storage facilities

When it comes to storage facilities, there are typically two main types: dedicated facilities and shared facilities. Each type has its own advantages and considerations, depending on the specific needs of the business or individual utilising the storage space.

Dedicated storage facilities are reserved for one customer, offering maximum security and privacy, ideal for high-value or sensitive items. These secure storage spaces provide customised solutions tailored to the customer's specific needs.

Shared storage facilities are used by multiple customers, sharing common resources and amenities. They are more cost-effective but may not offer the same level of security and privacy as dedicated facilities, as multiple parties access the same storage space.

Types of Storage Services

Climate-Controlled Storage

For businesses dealing with sensitive goods, such as electronics, art, or pharmaceuticals, climate-controlled storage is essential. These facilities maintain specific temperature and humidity levels to protect items from damage caused by environmental factors. This type of storage is crucial for preserving product quality over time and ensuring compliance with regulations in certain industries.

Cold Storage Warehouses

Cold storage warehouses are specifically designed to store perishable items, such as food, flowers, or medicines, at low temperatures. These facilities offer refrigeration and freezing capabilities to ensure that goods remain fresh and safe for consumption. For businesses in the food industry, having access to a cold storage warehouse is vital to meeting health standards and reducing waste.

Portable Storage Solutions

Portable storage units have gained popularity as a flexible storage option. These containers can be delivered directly to a customer's location, allowing for easy loading and unloading of items.

Bunded Storage

Bunded storage is a highly specialized type of storage solution designed for businesses that handle hazardous materials. Bunded storage units, typically equipped with secondary containment features, minimize the risk of spills and leaks, making them essential for compliance with health, safety, and environmental standards. These facilities not only ensure safety but also help businesses avoid costly fines and potential damage to the surrounding environment.

Key Features of Bunded Storage

Secondary Containment: Bunded storage areas are designed with a containment area that can hold any leaks or spills from the primary storage container. This feature is critical when dealing with liquids, such as chemicals or fuels, ensuring compliance with regulatory requirements and safeguarding the environment

Ventilation and Temperature Control: Many bunded storage units include proper ventilation systems and temperature controls to accommodate various types of hazardous materials. This aspect is vital to prevent the buildup of harmful vapors and to maintain the integrity of the stored substances.

Security Measures: Security is paramount in bunded storage facilities. Features often include secure locks, fencing, and alarm systems to deter unauthorized access and safeguard against theft or tampering.

Deep Storage

Deep storage is a strategic solution for businesses that require long-term storage capabilities for large volumes of inventory or equipment. This type of storage typically involves using higher or more specialized shelving systems to maximize the use of vertical space within a warehouse. Deep storage is particularly beneficial for companies managing seasonal stock, excess inventory, or products that are not frequently accessed.

Advantages of Deep Storage

Maximized Space Utilization: One of the primary benefits of deep storage is the ability to utilize warehouse space more effectively. By employing taller shelving units or racking systems, businesses can store a greater volume of goods while maintaining an organized layout.

Cost Efficiency: Deep storage solutions can help businesses save on rental costs by reducing the required footprint for their storage needs. When warehouse space is optimized, companies can often negotiate better lease terms or reduce overhead expenses.

Improved Accessibility: While deep storage may sound counterintuitive regarding accessibility, modern deep storage systems are designed with ease of access in mind. Many facilities utilize advanced technology, such as mobile shelving or automated retrieval systems, to ensure that stored items can still be accessed efficiently

Bulk Storage

Bulk storage solutions cater to businesses dealing with high-volume goods that require substantial space. This type of storage is advantageous for companies that deal with industrial or wholesale products, providing the capacity to store large quantities efficiently. Here are some key features and benefits of bulk storage solutions:

Economical Space Utilisation

Bulk storage facilities are designed to maximize space. With options like pallet racking systems, shelving units, and stacking bins, businesses can utilize vertical space effectively. This helps to reduce costs associated with rental fees and can result in better inventory management.

Enhanced Accessibility

Most bulk storage facilities are structured to facilitate easy access to goods. Whether through wide aisles for machinery or organized shelving, these spaces are designed to enable quick retrieval of items. This is particularly beneficial for logistics operations that require speedy fulfillment times.

Versatility in Warehouse Storage Options

Bulk storage facilities can accommodate a wide range of products, from raw materials to finished goods. They can handle various types of materials, including liquids, grains, and oversized industrial equipment, providing businesses with the flexibility they need to adapt to inventory changes.

Pallet Storage

Pallet storage is a common method utilized within bulk storage facilities to optimize space and streamline the storage process. This approach involves the use of standardized wooden, plastic, or metal platforms called pallets, which allow goods to be stacked efficiently and securely.

Should you want to expand you're knowledge to pallet delivery, FLOX have created a guide on how to choose the right pallet transport company for you.

Below are some significant advantages of pallet storage:

Space Optimization

Pallet storage systems make it possible to maximize warehouse space significantly. By employing vertical storage techniques and utilizing high racking systems, businesses can store more products in the same footprint. This efficient use of height can dramatically reduce the overall storage costs by enabling companies to maintain higher volumes of inventory without needing a larger facility.

Improved Inventory Management

With pallet storage, inventory can be organized systematically, making it easier to track movements and manage stock levels. Each pallet can be clearly marked and labeled, so that staff can quickly identify products and their locations. This organized approach facilitates efficient stock rotation, helping to minimize waste and ensuring older stock is sold or used before new deliveries arrive.

If the terms above are sounding alien to you then take a look at FLOX's guide to logistics jargon.

Critical Role of Distribution Centres in Supply Chains

Distribution centres stand as nerve centres in the supply chain, bridging the critical gap between production and the final consumer. These hubs operate at a breakneck pace, receiving products from suppliers, staging them briefly, and distributing them to their next destination, whether that be retail establishments, wholesale outlets, or directly to customers' doorsteps.

The demand-driven approach of these centres allows for products to whiz in and out, with fleets of trucks facilitating the transfer. The strategic placement of these centres is fundamental, often residing in central locations to maximise efficiency. The rapid dispatching from these locales translates into goods flowing from numerous sources to a multitude of destinations with swiftness and precision.

Benefits of Using Fulfilment Centres

Fulfilment centres are essential to e-commerce, ensuring online orders are stored, packed, and shipped efficiently. Upon receiving an order, these centres quickly select, prepare, and dispatch products to customers. Warehouses prioritise efficiency, aiming to store items safely and dispatch them promptly.

The swift processing and efficient storage solutions of fulfilment centres meet modern consumers' expectations for prompt delivery, making them invaluable to businesses.

The expertise and systems inherent in fulfilment centres allow for inventory optimization, alleviating the potential stresses of stock management. Companies leveraging these centres not only improve their order accuracy but also enhance overall customer satisfaction through reliable and speedy delivery of purchases.

We've expanded on this topic in our article discussing the benefits of fulfilment centres.

Evaluating Storage Needs and Capacity

Key factors in selecting a warehouse include accessibility, location, storage capacity, security, and specialised features like temperature control. These elements ensure the warehouse aligns with your business needs and scales with operations.

Modern storage facilities offer precise inventory management solutions with track and trace dispatch systems for real-time visibility. They provide services like container handling, break bulk management, order pricing, and product assembly.

Sophisticated options include bespoke storage, ISO9001 and OHSAS18001 standards compliance, and high security in both dedicated and shared facilities. Bonded storage for customs-controlled items and open storage for large items are also available.

Advantages of Outsourcing Warehousing Services

Outsourcing warehousing services provides businesses with a plethora of advantages, particularly for those grappling with the ebbs and flows of seasonal demand. Here are some key benefits:

Cost-Effectiveness: Utilising third-party warehousing facilities allows businesses to avoid the high overhead costs associated with owning and maintaining their own storage spaces. They can rent space on an as-needed basis, presenting an economical way to manage excess inventory during peak seasons.

Operational Efficiency: External warehousing services deliver a systematic approach to inventory organisation. This boosts efficiency by streamlining the retrieval process, thus enhancing accessibility and speeding up order fulfilment.

Strategic Locations: Warehouses are often strategically located near transport hubs or central business areas to minimise transit times. Drive-up units are one such provision that can accelerate the distribution process, meeting the need for quick and efficient client deliveries.

Scalability: Warehousing solutions provide flexible options that can be tailored to business size and demand. This scalability supports growth and ensures that businesses can adapt their storage requirements to match their inventory levels, making it easier to handle seasonal spikes and downturns.

|

Benefit |

Description |

|

Cost-Effectiveness |

Avoid capital expenses with pay-for-what-you-use models. |

|

Operational Efficiency |

Streamlined inventory systems increase accessibility and speed up distribution. |

|

Strategic Location |

Proximity to transport links shortens delivery times. |

|

Scalability |

Storage services that grow with your business needs, ideal for handling fluctuating demands. |

By opting to outsource their warehousing needs, businesses can leverage these benefits to not only save on costs but also elevate their service offerings to end customers, ultimately leading to greater competitive advantage and customer satisfaction.

Another important aspect of 3rd party warehousing and storage is the implementation of advanced technology and automation. Modern warehouses are equipped with state-of-the-art technology that allows for efficient inventory tracking, real-time data analysis, and automated processes. Automated storage and retrieval systems (AS/RS) and robotics play a significant role in enhancing the speed and accuracy of order fulfilment, reducing errors, and increasing productivity.

Effective warehouse management systems (WMS) which many of the 3rd party warehouse providers have, provide comprehensive control over inventory, from receiving and storing goods to picking, packing, and shipping them to the end customers. These systems enable businesses to optimise space utilisation, manage inventory levels, and ensure timely and accurate order fulfilment.

Outsourcing Storage Costs

In addition to the technological advancements that streamline warehouse operations, outsourcing warehouse and storage services can lead to significant cost savings. By leveraging third-party logistics (3PL) providers, companies can avoid the substantial capital expenditure associated with establishing and maintaining their own warehousing facilities. This can include expenses related to real estate acquisition or leasing, utilities, staffing, and equipment maintenance.

Flexible Pricing Models

Warehousing and storage services often come with flexible pricing models that can accommodate the fluctuating nature of business demands. Businesses can opt for pay-as-you-go plans or seasonal agreements that align with their inventory cycles. This adaptability allows companies to scale their storage needs up or down without the financial burden of fixed costs associated with owning a storage facility.

If you're looking to outsource your warehousing storage then take a look at our article on how to find the perfect warehouse rental near you. If you're set on London being the ideal location for your warehouse operations, FLOX have created another guide for that specific purpose. Take a look at the best warehouse spaces in London from FLOX.

Warehousing Requirements

before diving into the options available, it’s essential to understand your specific warehousing requirements. Each business has unique needs that determine the best storage solutions.

Inventory Volume

The first step in identifying your warehousing requirements is assessing the volume of your inventory. Understanding how much space you need will help you narrow down your options. Calculate the total number of items you plan to store and consider the space needed for shelving, pallets, and aisles between stacks of goods. A warehouse that is too small can lead to disorganization, while one that is too large may incur unnecessary costs.

Type of Goods

Consider the nature of the products you'll be storing. Are they perishable items that require temperature control, or are they non-perishable goods? If you deal with fragile items, make sure your warehouse has appropriate shelving and handling processes in place to mitigate any damage. Additionally, hazardous materials will need specialized storage and safety measures.

Accessibility & Location

The location of your warehouse is vital for efficient logistics. Consider proximity to major transport routes, such as motorway networks, railroads, and shipping ports. A strategically located warehouse can drastically reduce transportation time and costs, ensuring your goods reach customers and partners swiftly. Additionally, easy access to your facility can facilitate quicker pick-up and drop-off operations for suppliers and distributors, enhancing overall supply chain efficiency.

Overall, the world of warehousing and storage offers a wide range of services and solutions to businesses of all sizes. From dedicated facilities to shared spaces, advanced technology to automation, and strategic partnerships to customised solutions, businesses can find the perfect fit for their storage needs. With the right warehousing and storage services, businesses can optimise their supply chain, improve customer satisfaction, and gain a competitive edge in today's fast-paced market.

Embracing the Future of Warehousing and Storage Solutions

The evolution of warehousing and storage service solutions is pivotal to the modern supply chain. As businesses face increasing demands and the rise of e-commerce, the strategic utilisation of various warehousing offerings can significantly enhance operational efficiency and customer satisfaction. Whether opting for dedicated or shared facilities, leveraging third-party logistics providers, or integrating advanced technology, the right choices can transform logistics into a competitive advantage.

Reflecting on these insights, it's clear that re-evaluating your logistics strategy is not just beneficial but essential in today's market. Embracing flexible, scalable, and technologically advanced warehousing solutions can lead to cost savings, improved service levels, and a more agile response to market fluctuations. By prioritising these aspects, businesses can not only meet current demands but also position themselves for future growth and success.

If you don't yet have an account, simply search for Available Storage Capacity or list your Logistics Services with no monthly fees.

Sign up for the FLOX platform and start shaping the future of logistics today.